Hydro Excavators

The Name You Know. The Brand You Trust.

Vac•Con hydro excavators offer the highest quality pumps, blowers, and control systems. Our line of trucks and trailers can safely excavate around in-ground utilities without causing any damage and have what it takes to operate in extreme climates and temperatures. Whether you intend to excavate, trench, or daylight, be assured we have a machine that fits your needs.

The DNA of Vac•Con Hydro Excavators

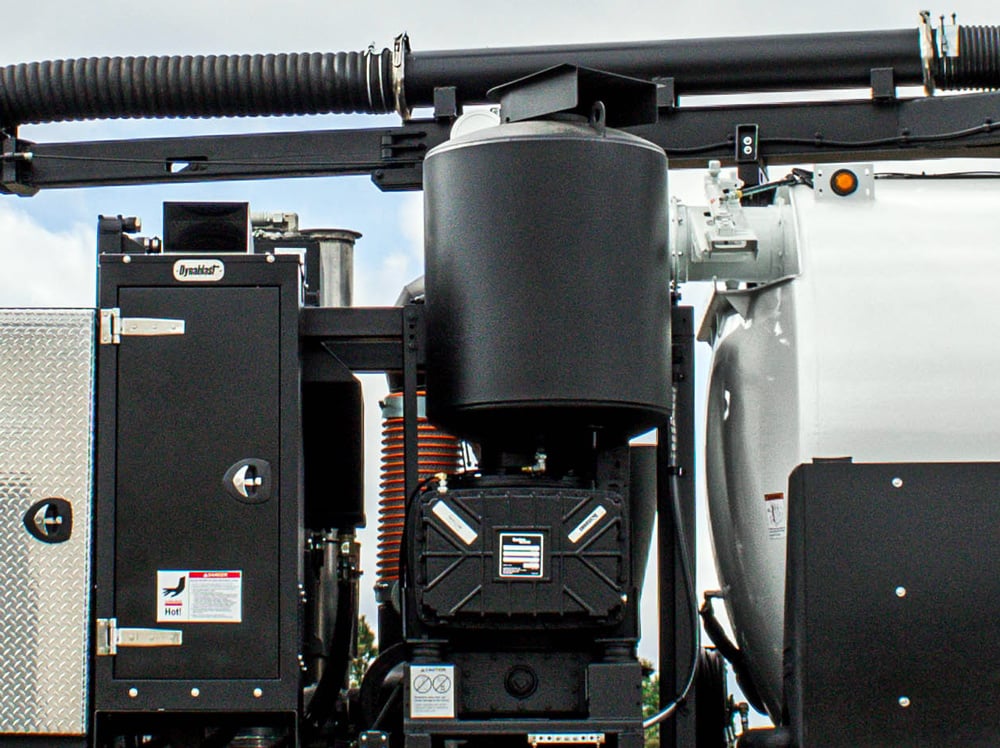

Vacuum

At the heart of our hydro excavation machines, Vac•Con has perfected the vacuum system. We offer positive displacement blowers and fan configurations to meet any requirement or application.

Water

Capacity and power are the most important factors regarding water for hydro-excavation machines. We offer a range of water tank capacities and jetting settings specifically tailored for the applications of every unit. We also understand the importance of reusing water and offer the most reliable, highest performing water recycling system on the market.

Payload

Bringing value and efficiency to our customers’ operations is the mission of our equipment. For that reason, we offer a range of debris tank sizes and will work with you to custom configure a machine that legally meets your payload expectations.

Filtration

If the heart of our machines is the vacuum, then the circulatory system is filtration. To offer the most reliable, highest performing machines on the market, we have engineered filtration systems that effectively collect and separate particles before they can reach

the vacuum system. In addition, we promote wet/vac operations to reduce dust production, extending the life of the vacuum system.

Operation

We know a machine is idle without an operator. For this reason, we prioritize improving operator efficiencies and ease-of-use across all our product lines. We’re proud to be the innovators of some of the most user-friendly components on the market.

Wireless Operation

All Vac•Con machines are available with wireless remote-control operations, increasing operator efficiency and unit ease-of-use. Our wireless remotes offer operation at an extreme range and are designed to withstand the harshest conditions, water, dirt, and debris. An integrated battery ensures that your power source is protected from the elements and recharges by magnetics on your machine.

Standard, Lightweight and PowerFlex Boom Options

Vac•Con offers a range of booms based on model, price, application, and operator preferences. Our standard booms are available in 6 and 10-feet models and 6-8-inches of vacuum intake hose. Our newest Lightweight Boom is available on X-Cavator models and features a boom rotation of 310-degrees. This boom can vertically lift 45-degrees and down 22 degrees for a huge range of motion. The PowerFlex Boom is a Vac•Con innovation that rotates 315-degrees, articulates 110-degrees, and lifts up to 34-feet. This boom telescopes out 8-feet for a reach of 28.5-feet from the truck and is top-mounted on the debris tank for front and rear maneuverability. PowerFlex is designed for a raking motion that allows operators to dig and trench without needing to move the machine.

Explore Our Hydro Machine Lineup

Available in chassis and trailer-mounted configurations, contractors and municipalities alike will discover that the X•Cavator family of products by Vac•Con are built to exceed their demands.